Tecnologia

Sustentabilidade

People

Área Reservada

EN

EN

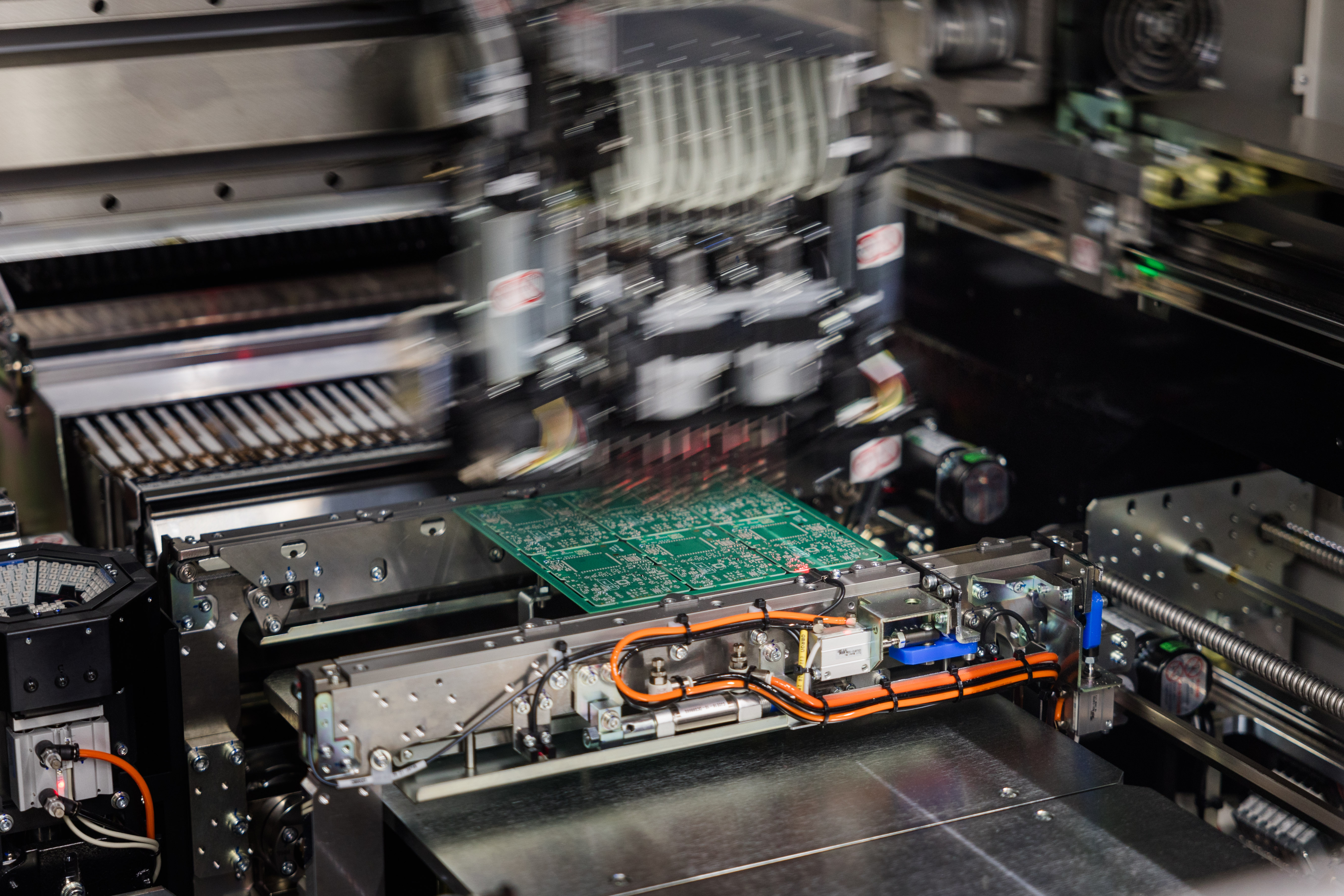

Our laboratory, our teams and our processes are prepared to support everything from prototyping to series production.

Services

Our cleanroom laboratory has been designed to provide a controlled and highly innovative environment, ensuring maximum precision and safety in every process. Equipped to meet our customers' needs, our lab is prepared for specialized productions, such as developing PCBA prototypes, with suitable conditions, including ISO 6/8 cleanrooms and a UV room.

At HFA we offer a comprehensive range of services, from simple to complex projects, with automated printing and assembly of series production quality. We also provide reflow technology using a Vapour Phase oven, PCB prototyping, and 3D object/tool fabrication. Our laboratory is also equipped with dedicated inspection, testing, and analysis equipment, ensuring an ideal space for innovation and excellence in every project.

We support our customers from the beginning of their product’s conception, development, and industrialization. We also provide expertise in technical and environmental feasibility assessments, expert recommendations, and guidance on construction rules to minimize process risks. We are also recognized for our assistance during the implementation and routing phases, including printed circuit board routing, ensuring a smooth and optimized workflow. We also offer our expertise in manufacturing customers’ products, including electronic boards, cables, and assemblies.

From PCB routing to prototype production, our specialized team uses methods and tools to control the quality and development timelines of customers’ products, and ultimately their series cost.

Micrography Reports

We provide detailed micrography reports, analyzing solder joints and material microstructure to ensure quality and reliability at a microscopic level.

Cleanliness Reports

Our cleanliness reports assess PCB cleanliness levels, ensuring they meet industry standards and preventing contamination issues that could affect product performance.

APQP Implementation

We implement Advanced Product Quality Planning (APQP) methodologies to ensure product and process quality from the early stages of development.

Production Reports

We generate detailed production reports, including yield rates, defect analysis, and process performance metrics, providing valuable insights for continuous improvement.

Test Fixture Design & Fabrication

We design and build custom test fixtures tailored precisely to your product's requirements. Our expertise encompasses integrating mechanical, electrical, and pneumatic components to create comprehensive testing solutions. We prioritize ease of use, maintenance, and scalability in our fixture designs, ensuring they meet your long-term testing needs.

Test Software Development

Our skilled engineers develop test scripts and software to automate your test procedures, increasing efficiency and repeatability. We integrate this software with your test equipment and data acquisition systems, providing a seamless testing environment. We also customize the software to accommodate your product's specific functionalities and testing requirements.

Test System Integration

We seamlessly integrate various test instruments and equipment into a cohesive test platform, ensuring all components work together harmoniously. This includes configuring test software and hardware for optimal performance and validating the entire system for accuracy and reliability.

Test Program Development

Our engineers create comprehensive test programs designed to exercise your product's specific features and functions under various operating conditions. We develop test cases and scenarios that cover a wide range of potential use cases, ensuring thoroughness and maximizing test coverage.

Comprehensive Testing

At HFA we develop and execute comprehensive test plans, including in-circuit testing (ICT), functional testing, and environmental testing, to guarantee product reliability and performance.

Advanced Inspection & Quality Control

We utilize advanced inspection techniques, such as X-ray inspection for internal component analysis, cross-section, micrography, and optical inspection for detailed solder joint evaluation, to ensure the highest quality standards are met.

Detailed Reporting

We generate detailed test reports and certifications, providing customers with documentation of product quality and compliance.

At HFA, we have integrated the Design for Manufacturability (DMF) concept as a fundamental stage in developing electronic solutions. This approach allows us to ensure that each product is designed with manufacturability in mind, optimising production processes early on, reducing lead times, and preventing potential failures.

Our focus is on making each product more efficient, reliable, and competitive, while always maintaining the highest standards of precision and innovation:

Analysis of customer documentation, according to customer requirements

Framing within legal and regulatory requirements, in the Standards, we are Certified

Manufacturing process design

We assist our customers in industrialization volumes efficiently, coordinating your supply chain, and optimizing production line setup. Our expertise ensures a smooth transition to high-volume manufacturing while maintaining quality and efficiency.

We manufacture production samples for customer evaluation and approval, allowing us to validate the design and manufacturing process before high-volume production.

We establish robust and repeatable manufacturing processes tailored to your specific product requirements. This includes conducting process capability studies, validating procedures, and documenting every step to ensure consistency and quality.

We collaborate closely with our customers, throughout the product development journey. Our expertise in Design for Manufacturing (DFM) analysis, prototyping, and pilot production runs optimizes the products for manufacturability and reduces time to market.

Other services

Ready to start?

Your technology deserves the best care. Contact us and discover how we can help.

Contact us

Where we are

Estrada da Zona Industrial, nº 337

3750-404, Águeda – PORTUGAL

geral@hfa.pt

comercial@hfa.pt

Phone

+351 234 612 680

+351 234 612 689

(Call to the national landline network)

Awards &

Certifications

Awards & Certifications

Phone

+351 234 612 680

+351 234 612 689

(Call to the national landline network)

Awards &

Certifications