Tecnologia

Sustentabilidade

People

Área Reservada

EN

EN

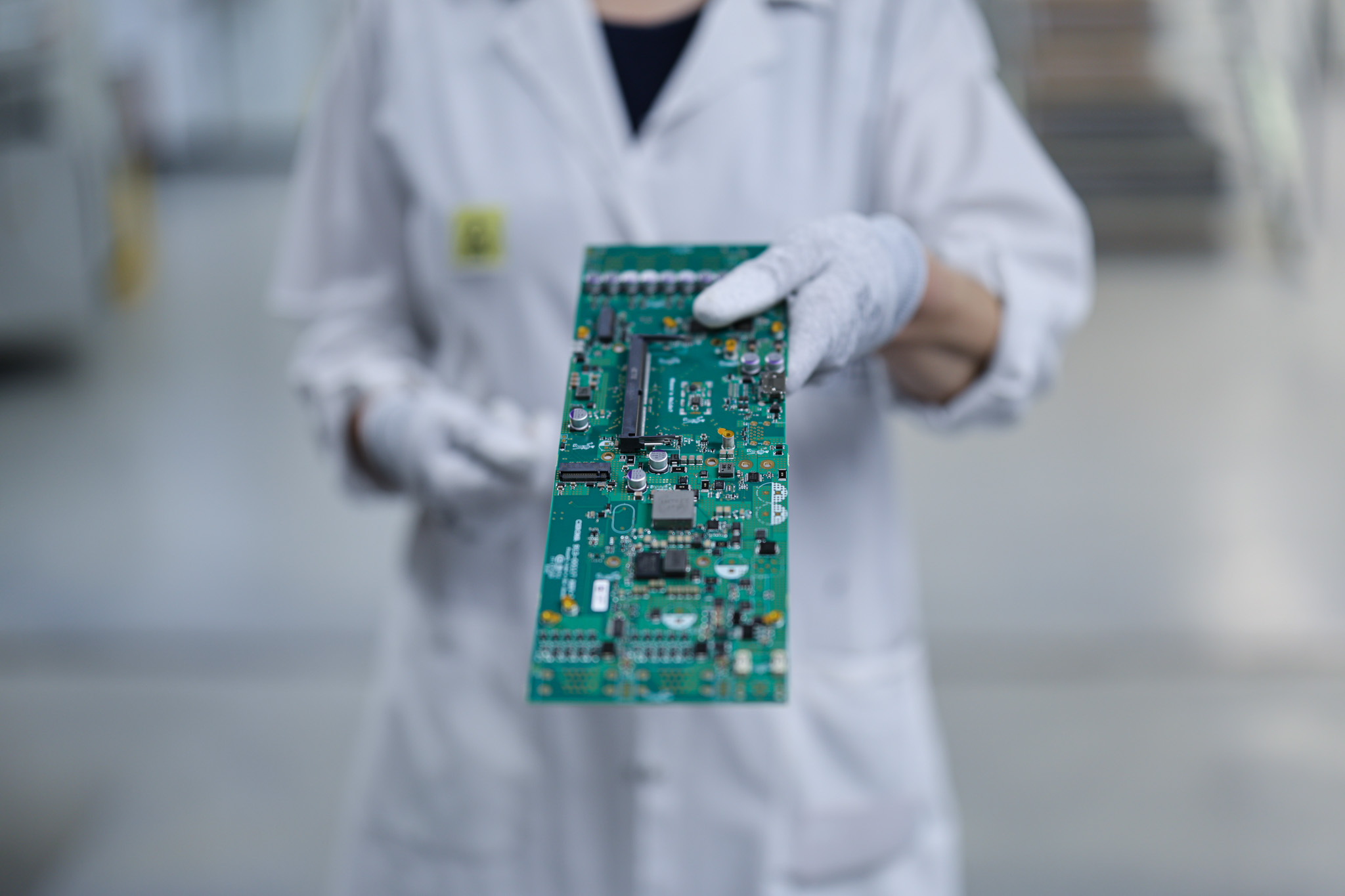

Our fully equipped SMT and THT assembly lines are prepared for high volumes and complex technical requirements

Services

High-Speed SMT Assembly Lines

Fully automated SMT assembly lines optimized for high-volume production

Capable of placing a wide variety of surface mount components, including 0100, 2920, BGA, LGA, QFN, QFP, PTH components - Pin in Paste, and more

Single and Double-Side SMT Assembly

High-precision placement equipment ensures accurate component placement and minimizes defects

Lines are configured for flexible production, accommodating different board sizes (Maximum L550mm × W490mm) and complexities

Achieve a production capacity of 1,000,000 CPH (IPC9820) for efficient and timely project completion

Comprehensive Quality Assurance

Automated Optical Inspection (AOI)

3D AOI systems meticulously inspect every board for component placement accuracy, solder joint defects, and other potential issues, ensuring the highest quality standards are met.

Solder Paste Inspection (SPI)

3D SPI systems analyze solder paste deposition to identify any inconsistencies before assembly, preventing potential soldering defects and ensuring optimal solder joints.

X-ray Inspection

For complex components like BGAs and LGAs… we offer X-ray inspection services to analyze hidden solder joints and ensure their integrity.

Supporting Services

Stencil Design & Fabrication

We guarantee stencil design and fabrication services, utilizing different types of stencils according to the complexity of the boards, like laser-cut, electropolished, or electroformed and nano-coating stencils for precise solder paste application.

Solder Paste Printing

Automated solder paste printing ensures accurate and consistent solder paste application to the PCB pads, optimizing solder joint quality.

PCB Cleaning

Advanced cleaning processes remove flux residues and other contaminants after assembly, ensuring the reliability and performance of your products.

Conformal Coating

Protect your PCBs from environmental contaminants and enhance their reliability with our conformal coating services. We offer a variety of coating materials and application methods to meet your specific needs.

Precision and Efficiency

Robotic welding units guarantee high precision, consistent quality, reduced defects and greater productivity in complex THT tasks.

Flexibility and Adaptability

Robotic systems adapt to different types of components and board sizes, offering versatile solutions for different assembly requirements.

Strict Quality Control

Visual inspection

Specialised technicians carry out rigorous visual inspections at every stage of the THT assembly process, guaranteeing the correct placement of components, the quality of welds and the integrity of the assembly.

Automated Testing

In-circuit testing (ICT) and functional testing ensure the performance and functionality of THT assemblies.

Support Services

Rework and Repair

Specialised rework and repair services ensure that any defects are corrected while maintaining quality standards.

DFM (Design for Manufacturability) Analysis

We analyse PCB designs to optimise THT assembly, reduce costs and avoid manufacturing challenges.

- Robust THT Assembly

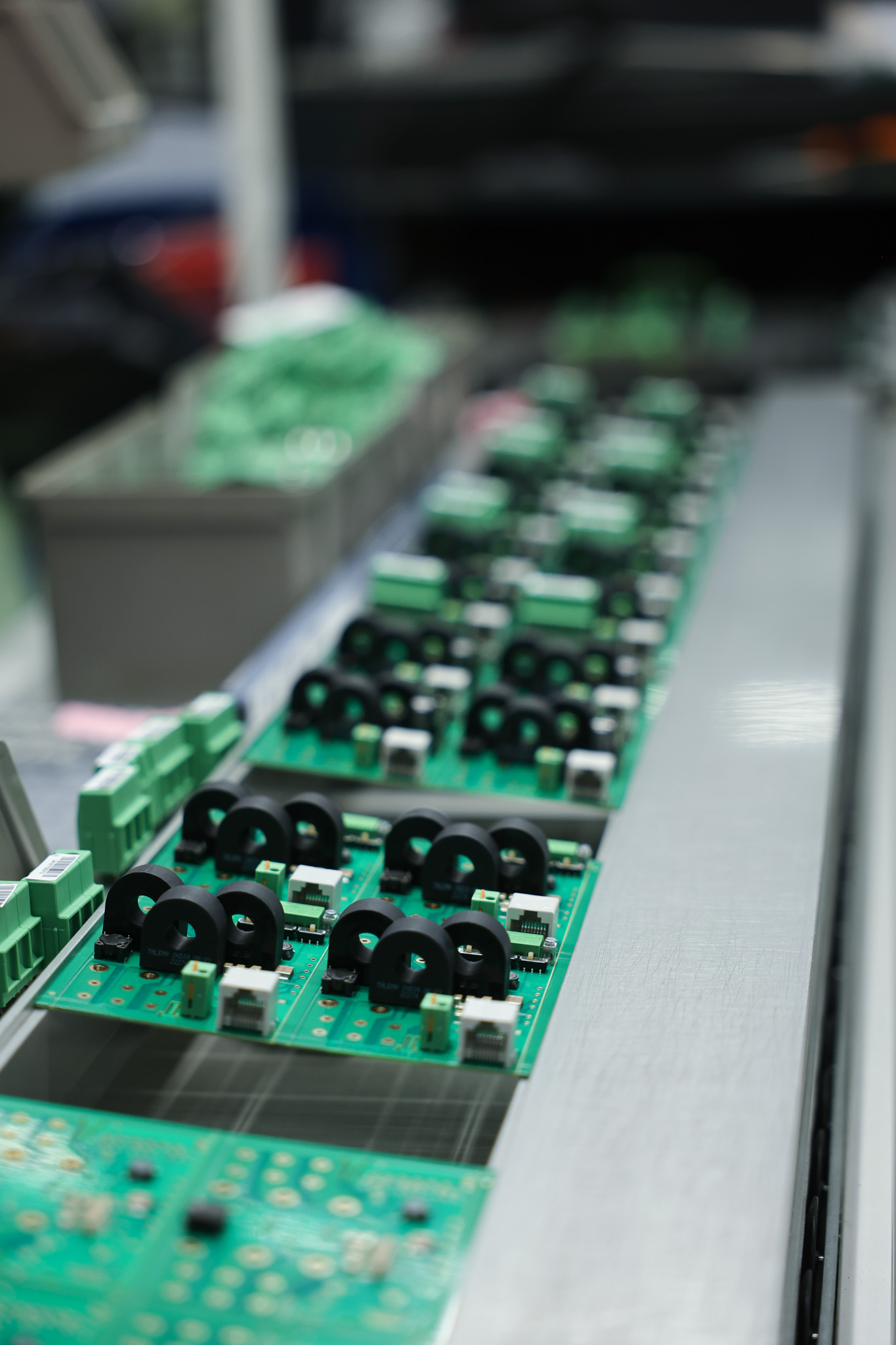

Automated and Manual Insertion

We offer both automated and manual through-hole component insertion, catering to diverse project needs and complexities. Our automated systems ensure high-speed and accurate placement for large-scale production, while our skilled technicians provide precise hand insertion for delicate or complex components.

Versatile Soldering Techniques

Wave Soldering: RoHS-compliant wave soldering machines enable high-volume soldering of through-hole components with lead-free processes, ensuring efficient and reliable connections. Automated flux application and solder wave control guarantee consistent solder quality.

Selective Soldering: RoHS-compliant selective soldering machines provide precise soldering for through-hole components minimizing thermal stress on sensitive components and ensuring optimal solder joint formation.

Hand Soldering: For intricate or specialized components, our expert technicians perform meticulous hand soldering, ideal for prototypes, low-volume production, or complex assemblies requiring exceptional precision.

Component Lead Preparation: We provide comprehensive component lead preparation services, including cutting, forming, and trimming, to ensure proper fit and optimal solderability.

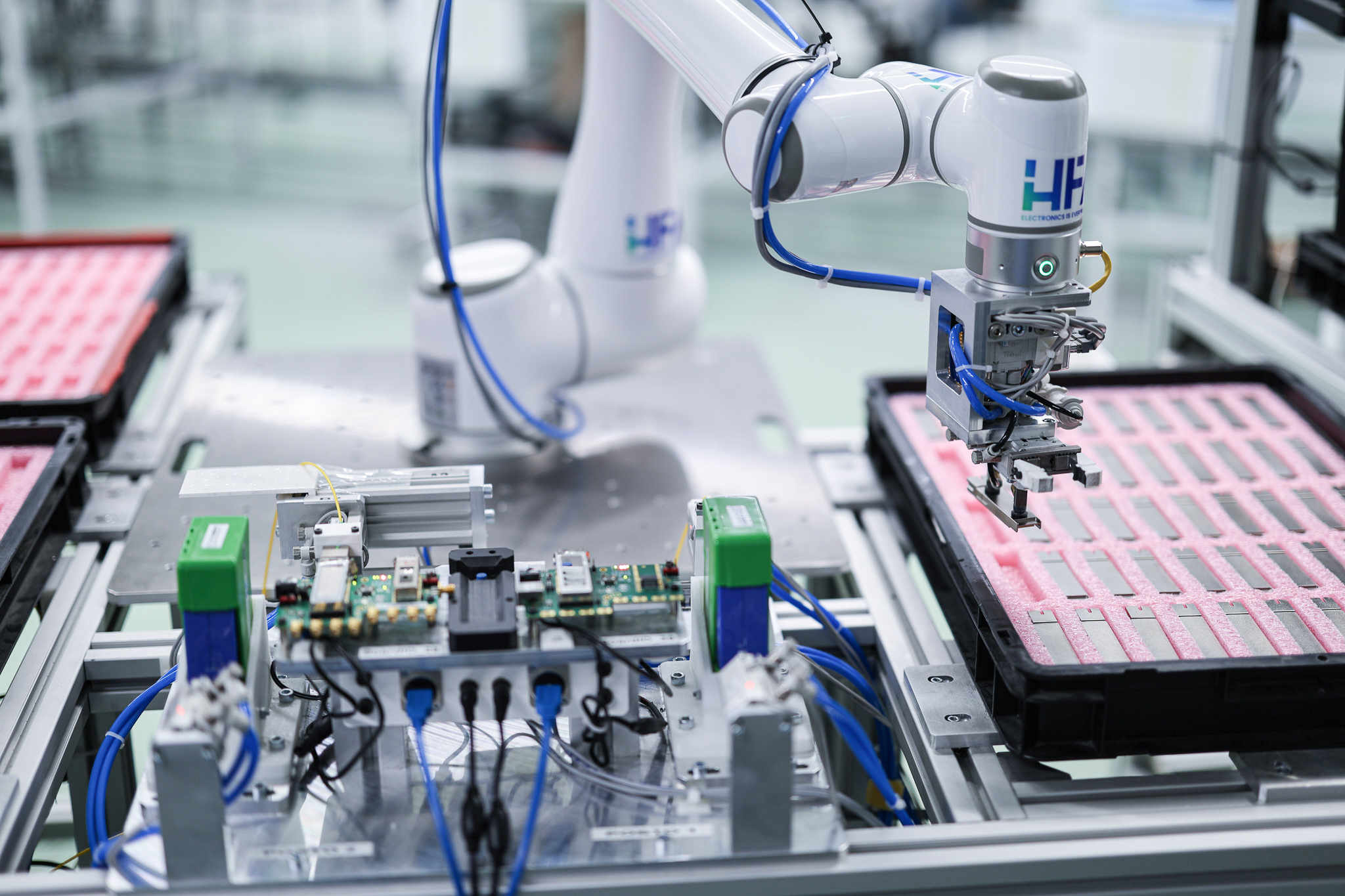

- Advanced Robotic Soldering

Precision and Efficiency

Our robotic soldering units provide unparalleled precision and efficiency for complex THT soldering tasks. These automated systems ensure consistent solder quality, minimize defects, and increase throughput for demanding projects.

Flexibility and Adaptability

The robotic soldering systems are highly adaptable, accommodating various component types and board sizes, offering a flexible solution for a wide range of THT assembly requirements.

- Stringent Quality Control

Visual Inspection

Our experienced technicians conduct thorough visual inspections at every stage of the THT assembly process, ensuring component placement accuracy, solder joint quality, and overall assembly integrity.

Automated Testing

Automated testing methods such as in-circuit testing (ICT), and functional testing testing to verify the functionality and performance of your THT assemblies.

- Comprehensive Support Services

Rework and Repair

Our skilled technicians provide expert rework and repair services for THT assemblies, ensuring that any defects are quickly identified and corrected to maintain the highest quality standards.

Design for Manufacturability (DFM) Analysis

We offer a DFM to optimize your PCB design for efficient and cost-effective THT assembly, minimizing potential manufacturing challenges and ensuring smooth production.

- Conformal Coating

We offer a wide range of conformal coating solutions to protect your PCBs and electronic assemblies from moisture, dust, chemicals, and other environmental contaminants. Our expertise encompasses various coating types, including acrylic, silicone, urethane, and more, ensuring the optimal choice for your specific application requirements.

- Application Methods

We employ diverse application methods, such as spraying, dipping, and selective coating, to achieve precise and uniform coating coverage. Our controlled curing processes ensure proper adhesion and optimal performance of the conformal coating.

- Potting & Encapsulation

For applications requiring extreme environmental protection, we offer potting and encapsulation services. This involves encapsulating electronic components or entire assemblies in a protective compound like epoxy, polyurethane, or silicone, providing robust mechanical support, thermal management, and electrical insulation.

- Advanced Coating Options

We also provide specialized coating services such as Parylene coating, offering ultra-thin, pinhole-free protection for sensitive electronics. Our masking and demasking techniques ensure the precise application of coatings to specific areas of the PCB.

- Quality Assurance

Coating Inspection

We conduct thorough inspections of coated assemblies to ensure uniform coverage, proper adhesion, and absence of defects, guaranteeing the effectiveness of the protective coating.

- Mechanical Depaneling

We use a variety of mechanical depaneling methods, including routing, scoring, and punching, to separate individual PCBs from multi-panel arrays. Our equipment and expertise ensure clean and accurate separation for various PCB sizes and materials.

- Automated Depaneling

For high-volume production, we employ automated depaneling systems, such as those equipped with a guillotine, for efficient and consistent separation of PCBs.

- Manual Depaneling

Our skilled technicians perform precise manual depaneling for delicate or complex PCB designs, ensuring no damage occurs during the separation process.

- Milling

We offer milling services for precise depaneling, especially for complex shapes or boards requiring intricate cut-outs.

- Quality Assurance

The control is carried out visually by specialized operators. Strain tests are conducted during the industrialization phase of new projects to ensure structural integrity and compliance with quality standards. These tests help identify potential weaknesses, optimize material performance, and verify that the final product meets the required specifications before full-scale production begins.

- In-Circuit Testing (ICT)

Our advanced ICT equipment performs automated testing of PCB assemblies with high speed and accuracy. This process efficiently detects manufacturing defects such as shorts, opens, missing components, and incorrect component values, ensuring the integrity of your circuit boards. We also offer on-board and out of board component programming (e.g., microcontrollers) as part of our ICT services.

- Functional Testing (FCT)

We develop and execute customized functional test programs to verify the overall functionality and performance of your assembled products. These tests simulate real-world operating conditions to ensure your products meet your specific requirements and perform reliably in their intended applications.

- Burn-in Testing

Our burn-in facilities subject your products to stress conditions, such as elevated temperatures and voltages, for an extended period. This process effectively identifies early failures and "infant mortality" issues, improving long-term reliability and reducing field failures.

- Advanced Testing Technologies

Boundary Scan

We utilize boundary scan (JTAG) techniques for testing complex PCBs with limited access to test points. This method allows for comprehensive testing of individual components and interconnections, ensuring high fault coverage and efficient debugging.

Ethernet Testing

We offer specialized Ethernet testing capabilities to verify the performance and compliance of your Ethernet-enabled devices. This includes testing data transmission rates, signal integrity, and conformance to Ethernet standards.

RF Testing

Our RF testing services evaluate the performance of your radio frequency devices, ensuring they meet your specifications and comply with relevant industry standards. We can test various RF parameters such as power output, frequency response, and sensitivity.

- Electrical/Optical Transmission Testing

For products involving electrical or optical signal transmission, we provide specialized testing to assess signal integrity, attenuation, and other critical parameters.

- Environmental Testing

Thermal Chamber

We utilize thermal chambers to expose your products to a wide range of temperatures, simulating extreme operating conditions and ensuring their performance and durability in various environments.

Environmental Stress Screening

We offer comprehensive environmental stress screening (ESS) services, combining temperature cycling, vibration, and humidity testing to identify potential weaknesses and improve product reliability.

- Other Specialized Testing

Gang Programming

We provide efficient gang programming services for simultaneous programming of multiple devices, reducing programming time and improving production efficiency.

Other services

Ready to start?

Your technology deserves the best care. Contact us and discover how we can help.

Contact us

Where we are

Estrada da Zona Industrial, nº 337

3750-404, Águeda – PORTUGAL

geral@hfa.pt

comercial@hfa.pt

Phone

+351 234 612 680

+351 234 612 689

(Call to the national landline network)

Awards &

Certifications

Awards & Certifications

Phone

+351 234 612 680

+351 234 612 689

(Call to the national landline network)

Awards &

Certifications