Tecnologia

Sustentabilidade

People

Área Reservada

EN

EN

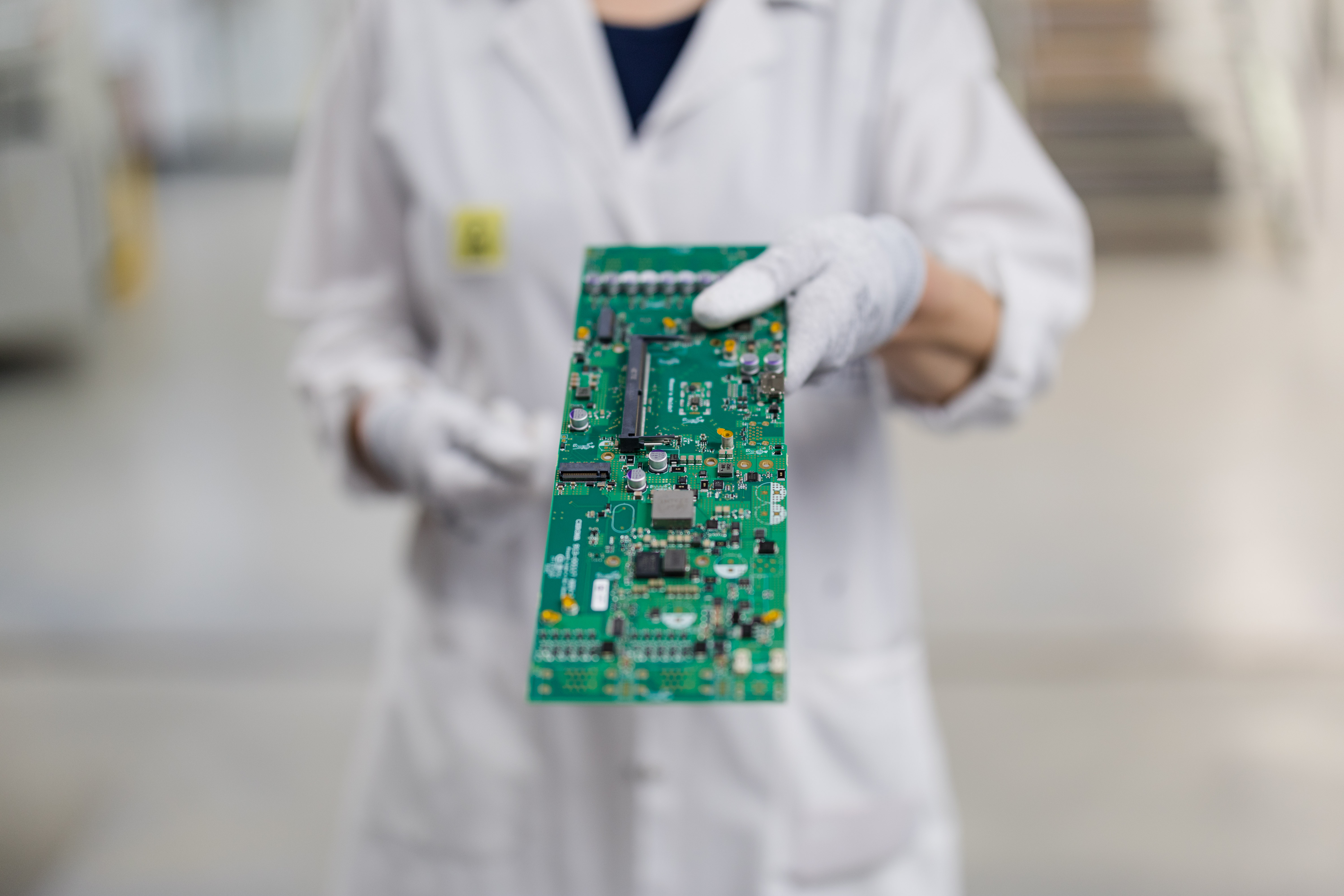

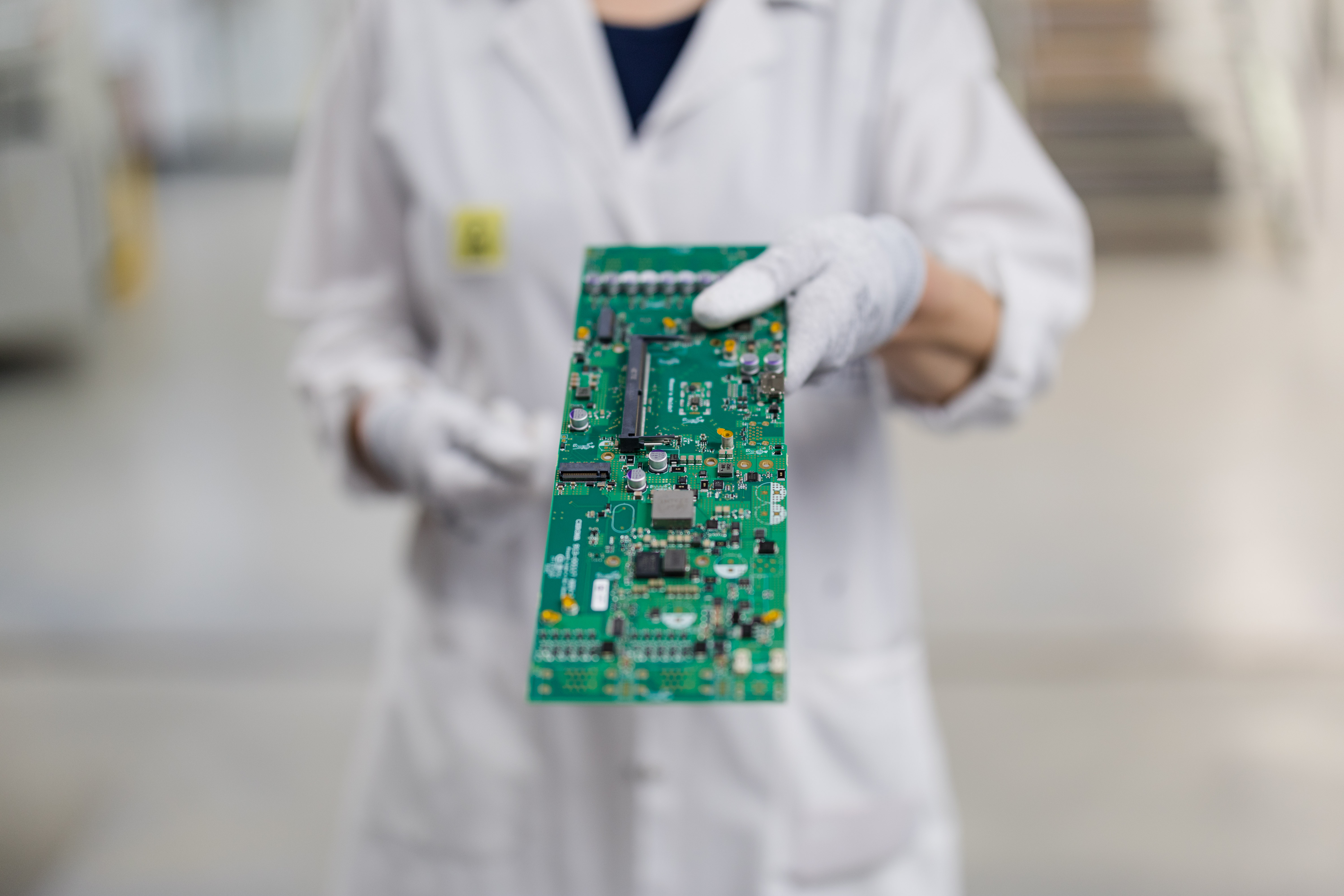

Is your design ready for the factory, or just the screen?

Designing a PCB is an art, manufacturing it is a science.

Even the most brilliant circuits can fail on the production line if they don't follow Design for Manufacturing (DFM) and Design for Assembly (DFA) principles.In collaboration with Professor Shlomi Zigdon, HFA presents the top 10 mistakes we see on the assembly floor.

1. Insufficient Thermal ReliefConnecting a pad directly to a large copper plane without "thermal spokes" acts as a heat sink. During soldering, the heat is sucked away, leading to "cold joints" or Tombstoning (where a component stands up like a gravestone).

2. Acid Traps (Acute Angles)When traces meet at angles sharper than 90 degrees, chemicals used in the etching process get trapped in the "V." This can eat away the trace over time, leading to intermittent failures months after the product is sold.

3. Solder Mask Defined vs. Non-Solder Mask Defined PadsUsing the wrong pad definition for BGA components can lead to pads lifting off the board or solder bridging. Choosing the right one depends entirely on the pitch of your components.

4. "Copper Slivers"Small, thin "islands" of copper left over during the design process can peel off during manufacturing and float around the board, causing random short circuits that are nearly impossible to debug.

5. Inadequate Clearance for Robotic NozzlesIf a tall component (like an electrolytic capacitor) is placed too close to a small SMD part, the robotic pick-and-place head may not have the clearance to seat the part properly, forcing expensive manual assembly.

6. Missing or Incorrect Fiducial MarksWithout clear, copper-defined fiducial marks, HFA’s automated machines cannot "align" themselves to your board's coordinates. This leads to offset components and poor solder alignment.

7. Vias-in-Pad Without CappingPlacing a via directly on a component pad without "plugging" it acts like a straw, sucking the solder away from the component and into the hole, leaving an open circuit.

8. Silkscreen on Solder PadsPrinting part labels or logos over a solder pad prevents the solder from bonding to the copper. This is a classic "rookie" mistake that leads to instant assembly failure.

9. Poor Drill-to-Copper SpacingPlacing a hole too close to a trace or internal plane can cause the drill bit to "wander" slightly and nick the copper, creating a short circuit inside the layers of the board.

10. Ignoring the "Component Courtyard"Every component needs a "safety zone." Ignoring these boundaries leads to parts physically overlapping or making it impossible for a technician to reach a part for testing or rework.

Don't let these mistakes delay your launch.

The SolutionMaster the Board. Master the Process

Learn how to "Catch the Snakes" before they strike. Join Professor Shlomi Zigdon at HFA for an intensive, presential DFM-DFA workshop. In this course, you will:

Align your designs with IPC-2221/2222 global standards.

Reduce your Time-to-Market by eliminating redesign cycles.

Get a Live Design Review of your current projects.

Course DetailsA DFM-DFA presential (in-person) course by Professor Shalom-Shlomi Zigdon who is a specialized training program for electronics engineers, focusing on bridging the gap between PCB (Printed Circuit Board) design and actual physical production. Professor Zigdon is a globally recognized expert and the founder of the High Tech Academy for PCB & Board Design. He is a veteran in the field with over 40 years of experience and serves on several IPC standards committees (the organization that sets the worldwide standards for electronics manufacturing).

Core Pillars of the Course

The course focuses on two critical methodologies that ensure an electronic product can be moved from a computer screen to a factory floor without costly errors or delays.

1. DFM (Design for Manufacturing)This part of the course focuses on the fabrication of the bare board.

Trace & Space: Ensuring copper widths and clearances meet factory capabilities to avoid short circuits.

Drill Analysis: Managing via sizes and aspect ratios so the manufacturer can actually drill the holes without breaking bits or causing plating issues.

Stack-up Design: Choosing the right materials (FR-4, high-speed laminates) and layer arrangements to ensure signal integrity and prevent board warping.

2. DFA (Design for Assembly)This focuses on the soldering and placement of components onto the board.

Component Clearance: Ensuring there is enough room for robotic pick-and-place nozzles to operate without hitting neighboring parts.

Thermal Relief: Designing pads so that heat is distributed evenly during soldering, preventing "tombstoning" (where a component stands up on one end).

Solder Mask & Stencil: Optimizing the apertures for solder paste to ensure strong, reliable connections without "bridging" (solder leaking between pins).

Why Study with Professor Shlomi Zigdon?

Taking a course from Shlomi Zigdon is often preferred by R&D teams because of his practical experience as HW Engineer and PCB Layout Designer, besides deep involvement with IPC Standards:

IPC-2221/2222: Generic standards on printed board design.

IPC-2251: Specific to High-Speed Board Design.

IPC-2226: High-Density Interconnection (HDI) design.

His teaching style is known for being highly practical. Rather than just theory, he uses real-world "horror stories" of board failures to teach engineers how to "catch the snakes" (his term for hidden design flaws) before they reach the manufacturer.

Key Benefits of the Presential Format

Hands-on Review: Students often bring their own design files for professional critique.

Networking: These courses are typically attended by senior hardware engineers, layout designers, and manufacturing managers from major tech firms (Intel, NVIDIA, Elbit, Rafael, Western Digital, Amazom, Google etc.).

Direct Interaction: Ability to discuss complex signal integrity (SI) and electromagnetic compatibility (EMC) issues in real-time, as long as time allows us.

This course is frequently held in technology hubs like Silicon Valley (Santa Clara) and Israel (Herzliya). Next one will be at HFA, Portugal.

Why HFA costumes should attend?

For HFA’s customers—primarily Hardware Engineers, PCB Designers, and R&D Managers—attending this course is a high-value investment that directly impacts their product’s success.

1. Stop "Designing in a Vacuum"

Most engineers design based on what their software allows, but software doesn't always reflect the physical reality of HFA’s assembly line.

The Benefit: Customers learn the "Why" behind manufacturing constraints. Instead of seeing HFA’s feedback as "restrictions," they understand them as "enablers" for a high-quality product.

Real-world impact: Designing a board that is "technically correct" but "physically difficult to build" leads to manual rework, which introduces human error.

2. Drastic Reduction in Time-to-Market

The "ping-pong" effect—where HFA sends a design back for corrections and the designer resubmits it—can add weeks to a project.

The Benefit: By learning IPC-standard DFM rules from Professor Zigdon, designers can get it "Right the First Time."

Real-world impact: A design that passes HFA's incoming inspection immediately can go into production 2–3 weeks faster than one requiring multiple redesign iterations.

3. Lowering Total Cost of Ownership (TCO)

Many engineers believe that the cheapest components lead to the cheapest board. Professor Zigdon teaches that Design is the biggest cost driver.

The Benefit: Customers learn to avoid "hidden costs" like:

Low Yields: If a design is prone to solder bridges, the customer pays for the scrapped boards.

Special Tooling: Complex designs might require expensive custom jigs or stencils.

Real-world impact: A slightly more "spacious" design might use a 10% larger board but result in a 99% yield instead of 85%, saving thousands of dollars in the long run.

4. Gaining a "Global Certification" Mindset

Shlomi Zigdon is an IPC Standards authority. This is the "international language" of electronics.

The Benefit: Customers don't just learn how to work with HFA; they learn how to design products that meet global standards (like IPC-A-610 or IPC-2221).

Real-world impact: This makes their products more reliable, easier to certify for medical or aerospace use, and more "future-proof."

5. Direct Access to a Legend

Professor Zigdon's courses are famous for the "Design Clinic" aspect.

The Benefit: Attending a presential course allows customers to bring their "problem boards" and get a live critique from a man who has seen millions of PCBs.

Real-world impact: Solving one specific thermal or signal integrity issue during the course can pay for the entire training cost in a single afternoon.

Summary Checklist: Why Attend?

Feature | Benefit for the Customer |

Expert Guidance | Learn from a world-renowned IPC/IEEE/EDICON trainer. |

Practical Skills | Move beyond theory to actual manufacturing "tricks." |

Error Prevention | Identify "snakes" in the design before they cost money. |

Networking | Exchange ideas with other engineers in the HFA ecosystem. |

Better Partnership | Speak the same technical language as HFA's factory team. |

Areas of expertise

Contact us

Ready to get started?

Contact us today to clarify any questions about our offerings and services.

Where we are

Estrada da Zona Industrial, nº 337

3750-404, Águeda – PORTUGAL

geral@hfa.pt

comercial@hfa.pt

Phone

+351 234 612 680

+351 234 612 689

(Call to the national landline network)

Awards &

Certifications

Awards & Certifications

Phone

+351 234 612 680

+351 234 612 689

(Call to the national landline network)

Awards &

Certifications