Tecnologia

Sustentabilidade

People

Área Reservada

EN

EN

About us

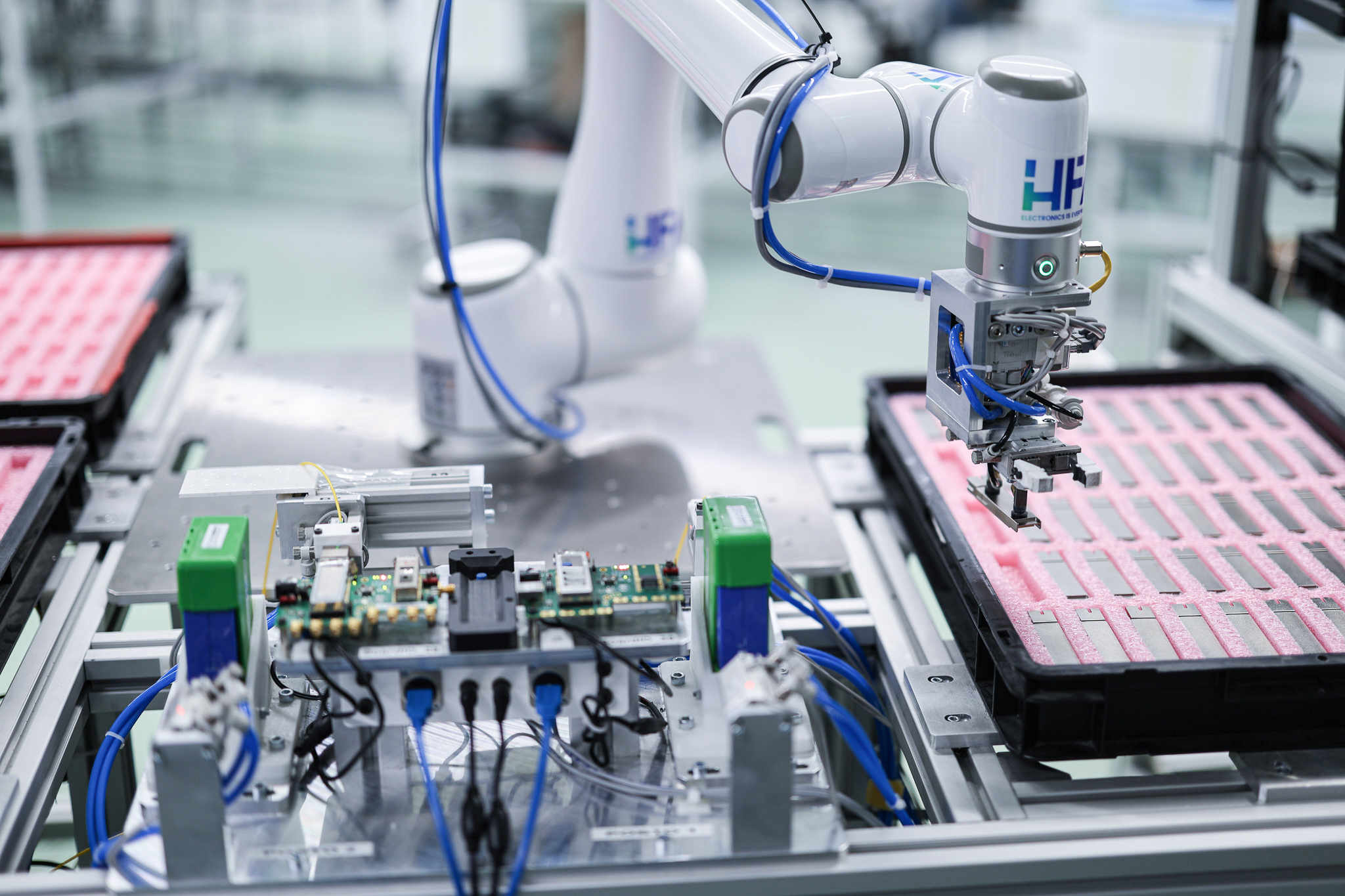

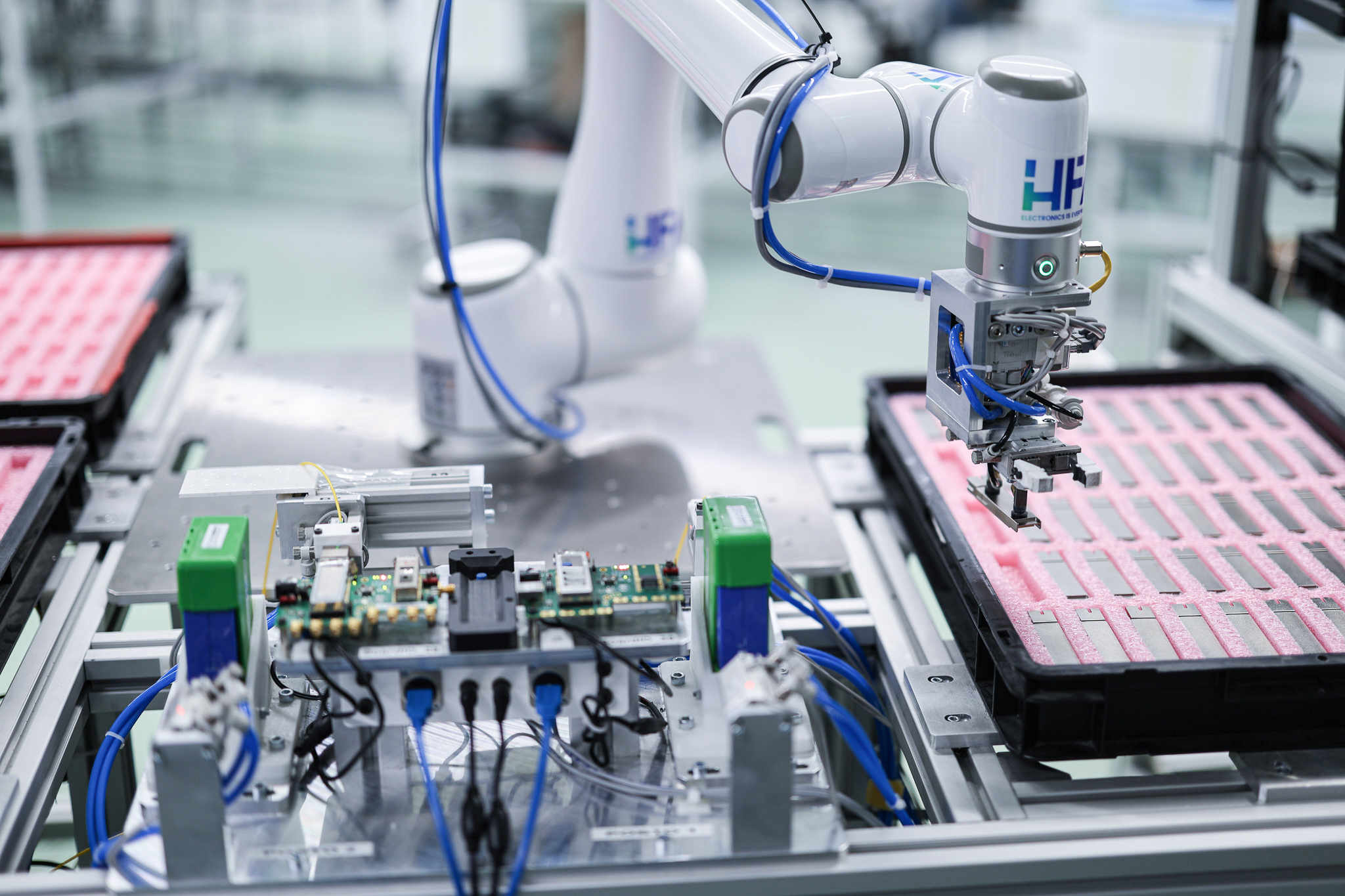

The Robotics Revolution at HFA: Efficiency and Precision with the Pick and Place Robot

At HFA, we're always thinking of new ways to innovate and optimize our processes. Today, we'd like to share with you a little about the use of robotics in our operations, with a focus on the Pick and Place robot.

How do we use them?

Currently, the Pick and Place robot is essential for moving parts in one of our test stations. It ensures that parts are placed and removed with precision, automating a task that would be repetitive and error-prone manually.

We are also working on a project to apply varnish using a robotic arm. This project is still under development, but promises to bring even more efficiency and innovation to our processes.

What is its applicability?

Robots can be applied to almost any repetitive task. In test stations, where the main task is simply to place and remove equipment, the implementation of robots is especially effective and easy to carry out. This automation not only increases efficiency but also the consistency of our processes.

Concrete examples of what we do

First implementation: We started with the TAG platform, which we developed ourselves, to test a customer's boards. The robot collected the plates from the loading tray, placed them in the test JIG and, at the end, organized the plates in the “OK” or “NOK” trays.

Second Implementation: The robot is currently at another customer, performing the same function, but for a different product. This continuity demonstrates the versatility and adaptability of our robotic solution.

Master's project: We have a second robot that is being used in a master's project, with the aim of varnishing boards. This project is an excellent opportunity to explore new applications for robotics in our processes.

Advantages of use

The use of robots in our processes brings numerous advantages:

Guaranteed repeatability: Each operation is carried out identically, reducing variations and increasing the quality of the end product.

Continuous production: Robots do not require breaks, allowing for uninterrupted production and increasing operational efficiency.

Increased output: Depending on the application, the use of robots usually results in an increase in production, responding better to market needs.

Operational silence: And of course, robots don't talk! 😊

Robotics is transforming the way we operate at HFA. Through the use of Pick and Place robots, we are optimizing our processes, ensuring a level of precision and efficiency that would be difficult to achieve manually. We will continue to explore and implement new robotic solutions to maintain our position at the forefront of technological innovation.

Areas of expertise

Contact us

Ready to get started?

Contact us today to clarify any questions about our offerings and services.

Where we are

Estrada da Zona Industrial, nº 337

3750-404, Águeda – PORTUGAL

geral@hfa.pt

comercial@hfa.pt

Phone

+351 234 612 680

+351 234 612 689

(Call to the national landline network)

Awards &

Certifications

Awards & Certifications

Phone

+351 234 612 680

+351 234 612 689

(Call to the national landline network)

Awards &

Certifications